| This set of winders is out of a boat from Delaware. They are in for just about a complete rebuild. There are quite a few problems with them, including a bad Pinion gear, bad bearings, worn clutches, and no brakes. |

|

|

We always seem to get parts in buckets for some reason. One of our customers says that if it weren't for the Five Gallon bucket we would go out of business. |

| This is the center support and bearings. The bearings are made of babbit and are fine on this support. |

|

|

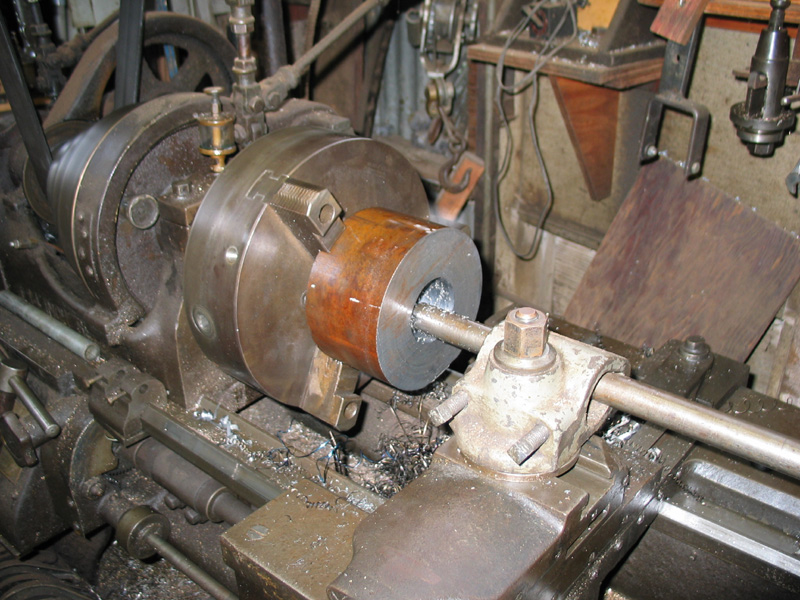

Machining the clutches was done on our big lathe. The original clutches were made of wood. Here Pop is turning the wooden inner faces so that epoxy will bond with it properly |

| In this picture the center portion of the winch has been chucked up and the faces are being remachined. |

|

|

One of these is the Pinion gear that was on the winch when it came in, you can see the wear on the teeth which was causing it to slip. |

| New Brake lining was epoxied into the drum portion of the clutches with West system epoxy. |

|

|

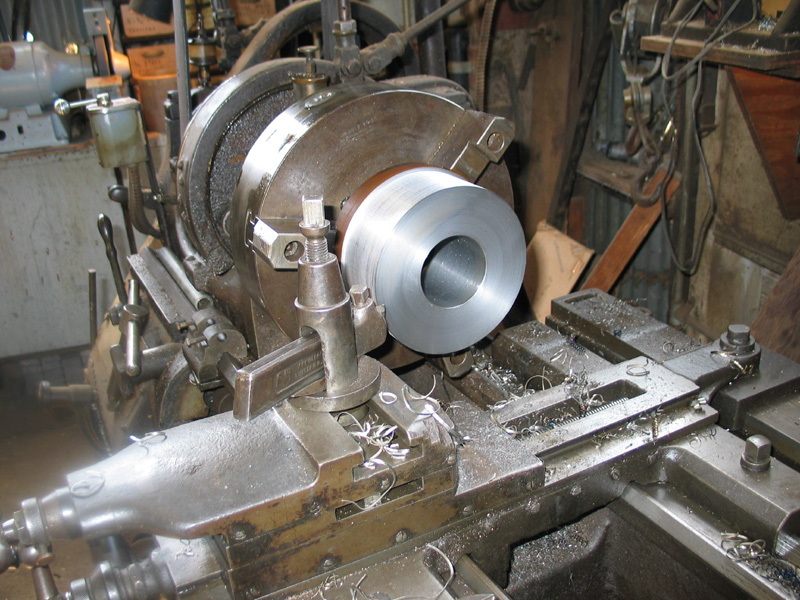

This is the blank for the new pinion gear. |

| The next step in making a pinion gear was turning the blank down to the correct size and shape. |

|

|

Here the blank is ready to go to the shaper. |

| With the blank mounted on a special jig the teeth were cut. This was a rather lenghty process. |

|

|

This the new shaft to hold the new pinion gear in place. |

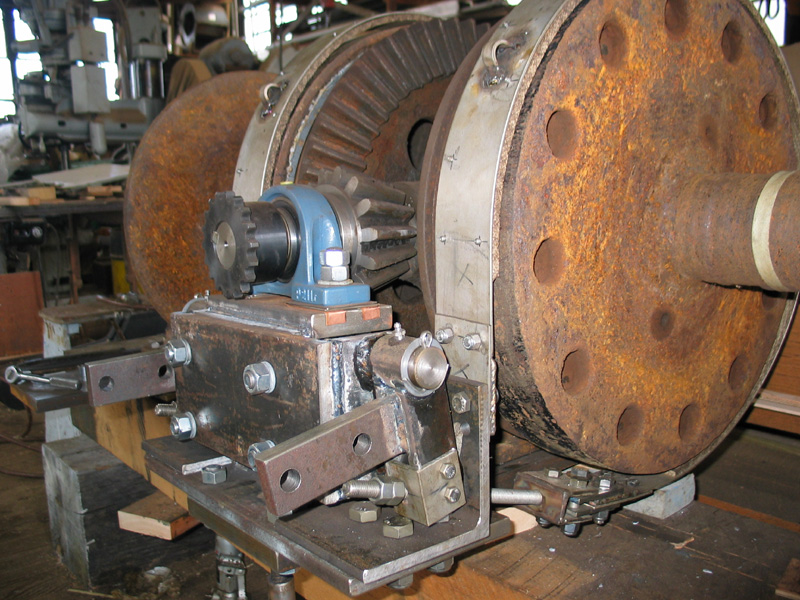

| This is a picture of the reassembled winch. The pinion is in place and has new supports to keep it rigidly in place. There are also new brakes in place. This set never had brakes and was not really designed for them. The brakes are engaged by lifting on the short arm with 2 holes in it. This tightens the band around the drum. The clips around the band are so the bands can have bungee cord attached to them so that when the brake is not engaged it won't be dragging on the drum. |

|

|

Now they are just waiting for the owner to arrive and drive them back to Delaware. |